The below snip is from Facebook. I haven’t seen anything prior about lubricating planetary gears. Is this accurate? If so, what’s the procedure?

That’s interesting. I haven’t seen any guidance on maintaining the drive train aside from greasing the tracks.

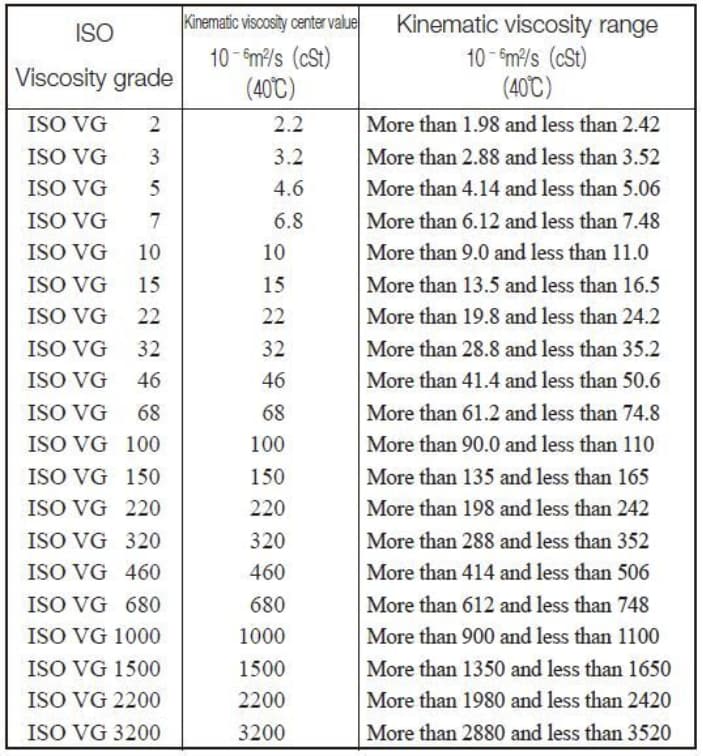

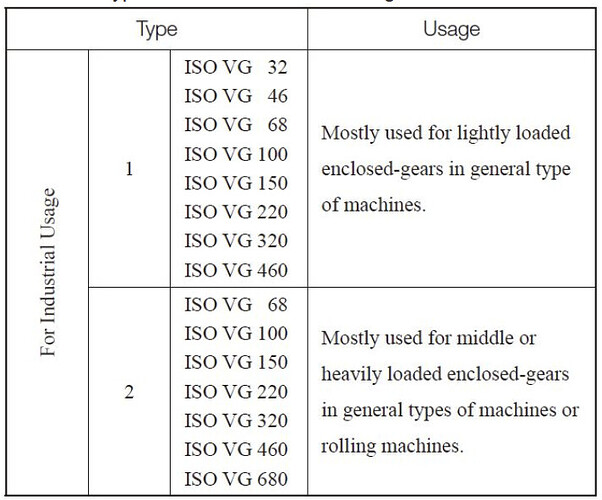

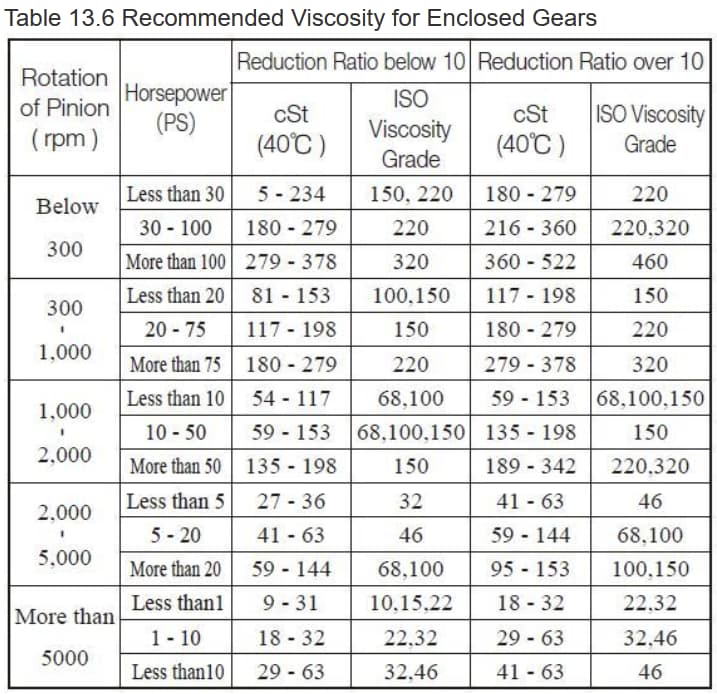

If they have planetary gears they’re encased in a sealed gearbox I’m sure. Dow Corning has Molykote PG 21as their plastic gear grease. This is an industrial grease that does not seem readily available (unless I want to buy a $200 tube of it on Ebay). But if it was open to do so it would take just a very small dab of it. Mobilgrease 28 is another great grease, again if it’s open case. Mobilgrease 28 is a supreme performance, wide-temperature, antiwear grease designed to combine the unique features of a polyalphaolefin (PAO) synthetic base fluid with an organo-clay (non-soap) thickener. Its consistency is between an NLGI No. 1 and No. 2 grease. It offers outstanding performance over a wide temperature range. The wax-free nature of the synthetic base fluid, together with its low coefficient of traction compared with mineral oils, provide excellent low temperature pumpability, very low starting and running torque, and can reduce operating temperatures in the load zone of rolling element bearings.

The clay thickener gives Mobilgrease 28 a high dropping point value of around 300?C, which provides excellent stability at high temperatures. Mobilgrease 28 resists water washing, provides superior load-carrying ability, reduces frictional drag, and prevents excessive wear. Tests show that Mobilgrease 28 lubricates effectively rolling element bearings under conditions of high speeds and temperatures. Mobilgrease 28 has also shown superior ability to lubricate heavily loaded sliding mechanisms, such as wing flap screw jacks. You don’t need much though less is more nylon gears are self lubricating anyway but a little dab of grease is a good idea.Or they maybe using using a lithium soap grease, NLGI number 1.A typical planetary gearbox has several load bearing elements which are in relative sliding motion to each other which causes heat to be released. The major sources of friction as well as heat are the meshing teeth between gears, thrust washers, thrust bearings and needle bearings. The lubricant performs the vital function of both lubricating these sliding interfaces and cooling these sources of heat, thereby preventing failure of the gearbox.

I learned way more than I thought I would need to know. I was expecting Yarbo to tell me what kind of grease to use, how often to use it, and where is the zerk fitting. ![]()

Wow! Thanks for the grease dissertation @dandbstephens ![]() But do we even need to do anything?

But do we even need to do anything?

Yeah, if it’s a sealed gear case, there will be no user maintanence, unless it becomes unsealed. If it is to be maintained, where is the zerk!

Tim